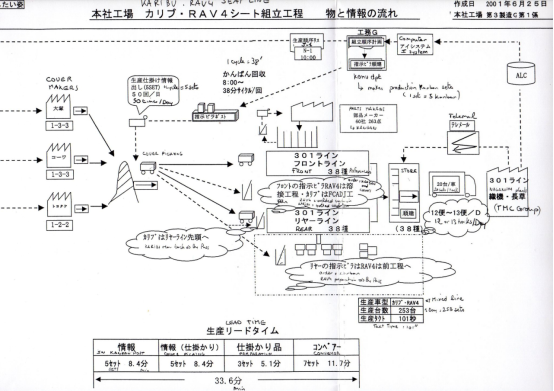

重要的事好像不只要讲三遍,michael 的领英又以刊头的「物与情报流图」说起。这是2001年,丰田织机的一个座椅工厂的「物与情报流图」的理想状态。主管是制造g的一位系长(副课长)。

当然本文不是在谈「物与情报流图」,而是更基础,更被忽略的—企业、制造的本质,制造的要素中—man, material, machine, method, money, information的man(society, 社会、社交、团队、小区),与information(顾客、后工程的信息)。

material, machine, method, money, 各家公司都有办法从市场取得,只有man 与information是各家的压箱本领,只能靠自己琢磨。

products and services are:

✅ engineered, made & delivered

✅ with work (labor) machines and process (capital) and working capital (parts, materials, stuff)

✅ supported by human capital (knowledge) and social capital (relationships)

forcing your customers to go through a website to purchase ( #nike ), outsourcing all your production (well, almost everybody) and bleeding your suppliers dry ( #purchasing ) comes down to choosing to ignore human and social capital:

➡ no need for #information flows

➡ no need for #trust

then, oh surprise, your system becomes increasingly inflexible and inefficient (as well unpleasant) and customers search for alternatives and look away and promised profits vanish and well, profit warnings and blahblahblah, business as usual.

#lean’s aim is to have suppliers as physically close to customers as can be to grow both #human and #social capital by focusing on #information flows before #material flows. toyota taught us to map material and information flows, and then solve problems of quality and lead-time collaboratively.

it’s not the problem solving per say that makes #lean companies perform better for society at large (as well as for their own people), but the resulting #knowledge and #trust from solving hands-on problems together, face to face.

global productivity comes from increasing human and social capital as you use labor, capital and working capital to deliver better products and services. relying alone on technical progress will simply not save you if the #humans in your system are left behind – just look at it!

所谓「产品和服务(企业的本质、利润的来源)」是:

✅ 设计、制造和交付

✅ 使用(劳动力)机器的作业和流程(资本)以及营运资本(零件、材料、物品)

✅ 由「人力资本(知识)和社会资本(关系)」支持

(反观主流的商业模式)强迫您的客户透过网站购买( # nike),外包你所有的生产( 好吧,几乎所有人),并榨干你的供货商( # 购买)归结为选择忽视「人力和社会资本」:

➡ 不需要情报流(关系者的连结)

➡ 无需信任(人的价值)

然后,哦,令人惊讶的是,你的系统变得越来越不灵活和低效(而且令人不快乐),于是客户寻找替代方案并移开视线,承诺的利润消失了,好吧,利润下滑和⋯⋯,一切照旧。

精益的目标是让供货商尽可能接近客户,在关注物流之前,先关注情报流来增加「人力和社会资本」。丰田教我们「绘制物与情报流图」,然后协作解决质量和前置时间的问题。

并不是解决问题的方法(技术),而是透过「面对面共同解决实际问题」,产生的「知识和信任」(社会),才让精益公司对整个社会(以及他们自己的员工)表现更好。

全球生产力来自于不断增加的「人力和社会资本」,因为您利用「劳动力、资本和营运资本」来提供更好的产品和服务。如果你系统中的「人(社会)」被抛在后面,只依靠「技术」进步根本无法拯救你-走着瞧吧!